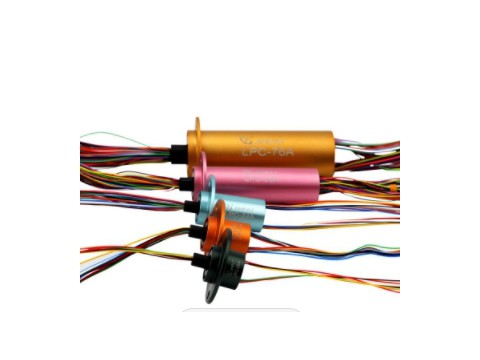

Shenzhen JINPAT Electronics Co., Ltd. is specialized in Industry and agriculture,Manufacturing,Design and processing since established in 10 years ago.So far,our company has established its branch companies in major cities throughout the country.Formed in Southern International Plaza,Yitian Rd,Futian District,Shenzhen China,Futian district,Shenzhen City,Guangdong Province,China as the center, the radiation sales system and service network.Details:4. If you want the slip ring to work very well in the equipment and the fit is very high, then the slip ring customization is very necessary, it can design the slip ring according to the specific needs of the equipment, but Before we customize the slip ring, do we have to know the slip ring very well? The slip ring is the most widely used slip ring in all slip rings. It is also called brush, carbon brush, collector ring, collector ring, bus ring, rotary, and rotary electrical joint. It is designed for unlimited use. When continuously rotating, the power supply and signal power are transmitted.As the name suggests, slip rings are the most widely used slip rings in all slip rings. They are also called brushes, carbon brushes, collector rings, collector rings, bus rings, rotary turns, rotating electrical joints, and special for slip rings. The power supply and signal power are transmitted during unrestricted continuous rotation. The stator and the rotor portion respectively lead the wires to connect the fixed structure and the power and terminal of the rotating structure, and rotate accordingly. According to its overall structure, it is divided into a real round slip ring (digging a hole in the rotating body, installing a slip ring), an empty smooth ring (installing the slip ring on the rotating shaft), and a separating slip ring, a flat ring slip ring, Mercury slip ring, special slip ring, etc.Slip ring customization can also be made into various special shapes according to the use, mixed transmission power source, light source, fluid pressure source, or used with other electrical components, such as: special profile, large shape, connected gear, sprocket, pulley , plug, power supply and light source mixing, power supply and pressure fluid mixing, equipped with optical, electrical, acoustic, temperature sensors, fiber optic transceivers, pressure gauges, pneumatic components, etc., combined into a multi-functional electrical components assembly to save Space, simplify the special requirements of the design structure.